Digital twin technology is being used by an increasing number of companies to monitor and control assets and processes using a virtual representation of physical spaces. Analyst firm Gartner predicts that by next year, half of large industrial companies will use digital twins, resulting in those organizations gaining a significant improvement in effectiveness.

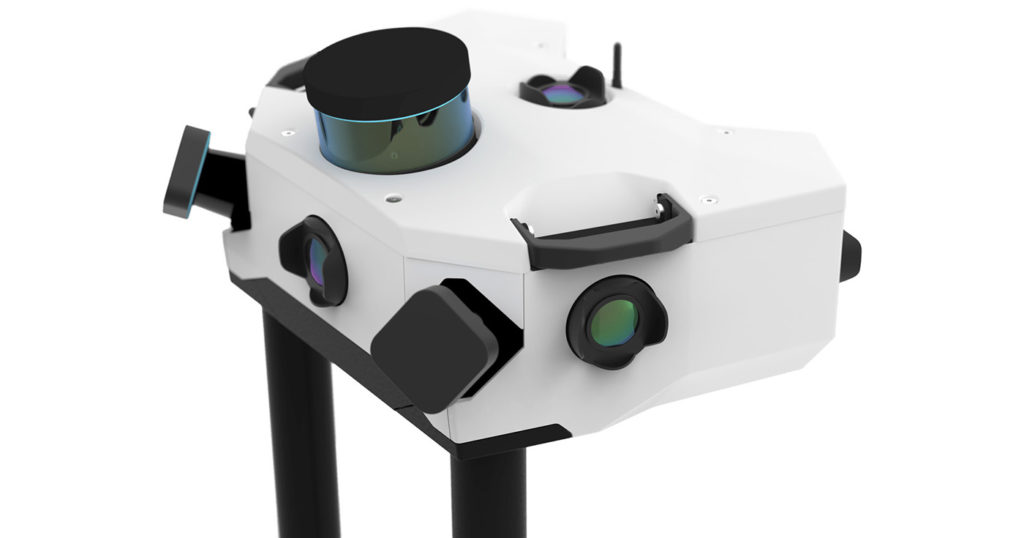

NavVis, an Automated with Velodyne partner, provides indoor spatial intelligence solutions for enterprises to generate survey-grade scans of complex building environments, like production facilities and construction sites. The company equips its NavVis M6 and NavVis VLX mobile mapping systems with Velodyne Puck LITE™ sensors, so that laser scanning professionals can capture the data needed to create digital building information and models.

To dive deeper into NavVis and how their solutions make it fast and easy to capture indoor data so that companies can take their commercial and industrial properties digital, we connected with Georg Schroth, NavVis Co-founder and Chief Technology Officer.

Georg: NavVis specializes in next-generation mobile mapping technology for reality capture of the built environment. Large buildings can be scanned in 3D at great speeds with our devices, NavVis M6 and NavVis VLX. And users can interact with their scanned buildings as though they were physically on site using our browser-based software, NavVis IndoorViewer.

The company vision is to empower every enterprise with the easiest and most powerful way to build and operate their digital twin. Our portfolio of hardware, software and cloud solutions is trusted by market-leaders in the automotive, manufacturing, construction and laser-scanning industries, and they’ve benefited enormously from optimized business performance and increased efficiency in production.

Georg: Enterprises engaged in modern production planning and management are facing some major challenges. First, global planning processes are becoming more expensive because of shorter product life cycles. Production lines must be altered and modified frequently for the next product generation. The second is having up-to-date information about their properties, wherever they’re located around the world, so that management can take critical decisions quickly and with absolute confidence.

For example, if you were to create a digital copy of a factory and populate it with current data at the correct locations, multiple workflows in the areas of planning, operations, continuous improvement, industrial engineering or maintenance would be dramatically enhanced. So, the benefits for enterprises become clear; increased transparency, improved remote collaboration, quicker decision-making, higher efficiency of workflows – even a smaller carbon footprint from reduced travel.

Another factor is restrictions on movement because of the COVID-19 crisis, which had a big impact on global manufacturing operations. If we hit a second wave of infections, our customers are prepared with enterprise-ready digital twin solutions that maintain continuity of operations while still protecting their workforce.

Georg: A static laser scanner is exactly that – static. They’re fixed in position as they operate, so that even the most basic reality capture project becomes generally slow, laborious and expensive. Our mobile mapping devices are capable of more than that. They can reliably track their position with precision – in all 6 degrees of freedom – for extended periods of time, even when objects might be in motion around it. NavVis is world-class in its ability to achieve the degree of accuracy in mobile mapping that surveyors require. The key innovation at work here is a technology called Simultaneous Localization and Mapping (SLAM), which first emerged in robotics and autonomous driving projects from the likes of Google and Apple.

Georg: We chose Velodyne sensors to provide real-time 3D data to our mobile mapping systems because we believe their data quality is the best on the market. Compromising by using a lower-specification or low-cost component simply isn’t an option for us. Sensors like the Velodyne Puck LITE have played an essential role in developing the industry-leading SLAM algorithms which power our flagship mobile mapping system, NavVis M6.

Over the course of development for NavVis VLX, a wearable mapping system with the same groundbreaking SLAM technology in a more compact design, it was a natural engineering choice to go with the Velodyne Puck LITE once again. The strategic placement of each sensor meant we could strike exactly the right balance between completeness of capture and speed of scanning. We’re delighted to have Velodyne as a technology partner, so that we can continue to provide laser scanning professionals with fast, dependable tools that deliver survey-grade results when scanning buildings.

Georg: NavVis VLX is a versatile yet powerful device that’s ideal as the primary scanning device for most building documentation projects. While the pricing is comparable to what you’d pay for a high-quality terrestrial laser scanner, there’s the added advantage of being up to 10x faster during data acquisition. The accuracy of the device is suitable for typical as-built documentation needs, such as LOD 300 BIMs or floor plans with a scale of up to 1:50.

Thanks to the NavVis SLAM and processing technology, we believe the point cloud accuracy and quality are best-in-class with low noise levels, homogeneous point cloud structure, and realistic coloring. The relative accuracy of the point cloud is better than 8mm. Plus, we provide a reliable and scalable workflow to register point clouds using control points (surveying targets). NavVis VLX will also pick up new innovations as part of our software updates going forward; customers can be assured that a NavVis VLX they buy today will fully benefit from further advances in data processing and quality.

Velodyne Lidar (Nasdaq: VLDR, VLDRW) ushered in a new era of autonomous technology with the invention of real-time surround view lidar sensors. Velodyne, a global leader in lidar, is known for its broad portfolio of breakthrough lidar technologies. Velodyne’s revolutionary sensor and software solutions provide flexibility, quality and performance to meet the needs of a wide range of industries, including robotics, industrial, intelligent infrastructure, autonomous vehicles and advanced driver assistance systems (ADAS). Through continuous innovation, Velodyne strives to transform lives and communities by advancing safer mobility for all.