The oil and gas industry is identified year over year as one of the most dangerous work sectors and, although procedures and protocols are tighter than ever, issues around safety in offshore drilling persist. Workers on the drill floor of an oil and gas platform perform jobs where moving heavy equipment could endanger them. These high-risk sectors are called red zones and are areas targeted for improved safety management in the industry.

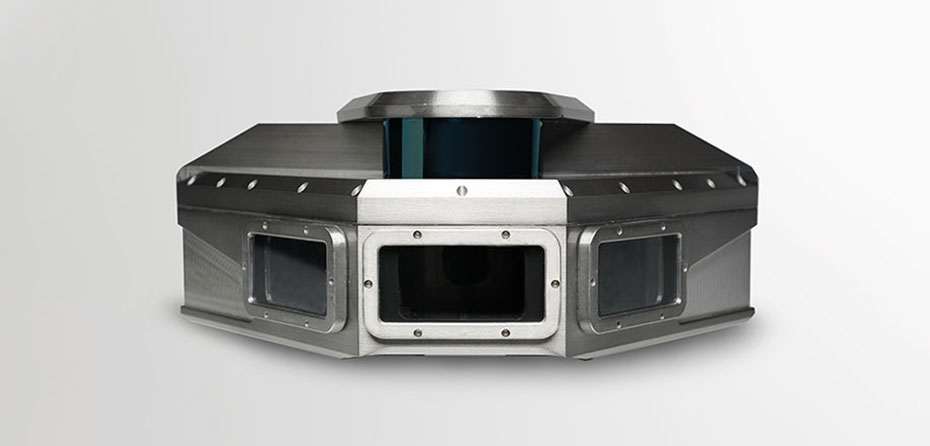

The Marsden Group, a global technology company specializing in complex industrial environments, is looking to increase efficiency and safety in offshore drilling, thereby transforming these critical offshore operational zones. It has developed Vision IQ, equipped with a Velodyne Puck™ sensor, to enable the accurate tracking and monitoring of personnel. The Vision IQ system sends audible and visual alerts to operators should hazards occur, making safety the number one priority.

Furthermore, Vision IQ has been comprehensively and strenuously tested against industry directives to ensure compliance for zones requiring increased safety in potentially explosive atmospheres. The Velodyne Lidar-equipped solution meets IECEx/ATEX certifications, which cover the use of equipment and protective systems in explosive atmospheres. This opens the door to further extending the use of Velodyne’s lidar solutions across industries that require adherence to explosive rated directives.

“Vision IQ empowers oil and gas companies to improve operational safety within critical red zone areas and even identify opportunities to improve working procedures and operational efficiency. Our unique combination of Velodyne lidar sensors and computer vision cameras delivers extremely accurate human detection and classification with minimal hardware and minimal effort to install and setup.” said Andy Pratt, CEO & President, The Marsden Group.

Using Velodyne’s lidar sensors, the Vision IQ application allows companies to track, monitor and play back human activity over time to better understand human movement, trends, and comparisons during specific rig activities. This information sets the stage to further improve efficiency and safety moving forward, which has the potential to advance the protection and security of workers throughout this high-risk industry.

Velodyne Lidar (Nasdaq: VLDR, VLDRW) ushered in a new era of autonomous technology with the invention of real-time surround view lidar sensors. Velodyne, a global leader in lidar, is known for its broad portfolio of breakthrough lidar technologies. Velodyne’s revolutionary sensor and software solutions provide flexibility, quality and performance to meet the needs of a wide range of industries, including robotics, industrial, intelligent infrastructure, autonomous vehicles and advanced driver assistance systems (ADAS). Through continuous innovation, Velodyne strives to transform lives and communities by advancing safer mobility for all.