Covestro is a leading supplier of high-tech polymers that are used in industries such as automotive, construction and electronics. They create plastics, adhesives, coatings and more that enable or improve countless products that surround us each day. For example, in the automotive industry, Covestro’s Makrofol ST352 near-infrared transparent film supports the development of embedded sensors, which are essential for autonomous and assisted driving technologies. In particular, this product addresses the need for a tinted film in lidar applications, such as front modules for electric vehicles.

Like Velodyne, sustainability is one of the driving forces behind Covestro’s product development. Covestro products help companies replace traditional materials with durable, light, more environmentally friendly and cost-effective materials. Enabling lightweight construction in the automotive industry and increasing energy efficiency of living spaces through the use of new insulating materials are just two examples.

We interviewed Nan Hu, Head of Electronics & Electrical Global Industrial Marketing at Covestro Engineering Plastics, to learn more about the company and how their products benefit lidar applications.

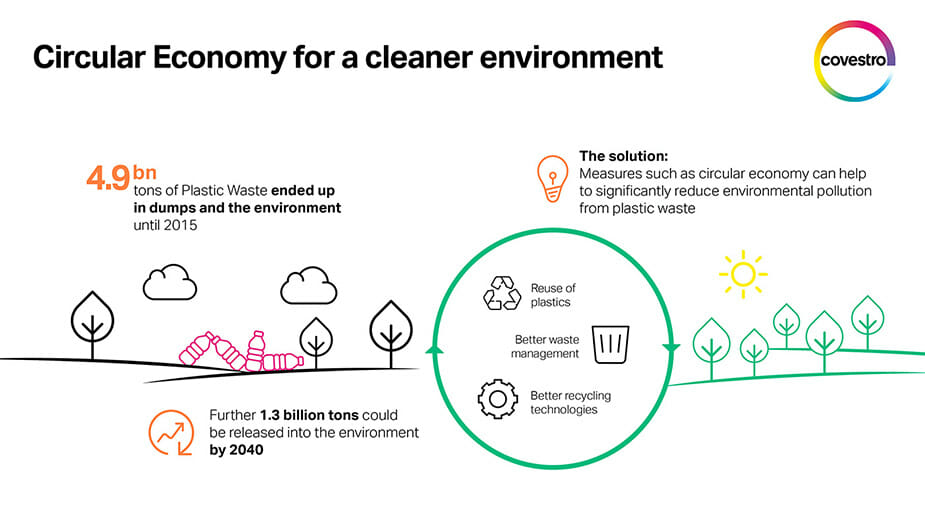

The Circular Economy is our vision and the guiding principal for everything we do. Our primary aim is to maximize the use of limited resources and to view used products as a resource so we can manufacture in a truly sustainable, climate-neutral way.

Covestro is fully committed to the Circular Economy so that we can help solve the pressing challenges of our time and help pave the way to a climate-neutral economy that conserves resources. With 2021 sales of EUR 15.9 billion (~$16.2 US), Covestro is among the world’s leading polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative, sustainable solutions for products used in many areas of daily life.

Covestro’s Engineering Plastics business entity offers differentiated material solutions to the electronics & electrical, mobility and healthcare industries, with eight production sites and more than 1,500 employees around the world. The high-quality materials that Covestro develops and produces are the key to a sustainable future.

Covestro’s mission dictates how we will achieve our vision to be fully circular: We want to promote innovation and growth with profitable products and technologies that benefit society and reduce the impact on the environment. At Covestro, our goal is to embed circular economic principles into the fabric of our operations and be a trailblazer for the entire plastics industry. To this we are focused on four main areas: alternative raw materials, innovative recycling, joint solutions and renewable energy.

This year, the Engineering Plastics group announced our new targets to become climate neutral and achieve net zero emissions by 2035. The targets include cutting greenhouse gas emissions from its own production as well as from external energy sources by 60 percent to 2.2 million metric tons by 2030. At the same time, we also intend to offer products that meet our customers’ climate objectives.

To meet the market demand for more sustainable material solutions, Covestro Engineering Plastics is adopting a comprehensive strategy that focuses on the development of more sustainable material offerings, such as bio-circular and recycled solutions. The strategy also includes a focus on design concepts and practices that are embedded in circularity, as well as building partnerships to create new business models in all of these areas.

In the age of intelligent connectivity, lidar solutions are instrumental to the connected life of human beings. Lidar sensors require high resolution, precision, reliability, robustness and power efficiency. Increased need for sustainability also calls for circular solutions in lidar sensors without compromising product performance. Covestro Engineering Plastics offers a comprehensive portfolio supporting lidar applications, with excellent optical performance and a good balance in mechanical, thermal and processing properties. This brings our customers high performance, reliable, lightweight and sustainable material solutions.

For example, our Makrolon® IR series would be an ideal material solution for a lidar window, with high IR transparency and customized cut-off. For structure components, we have materials reinforced by glass fiber and carbon fiber, providing good mechanical property, high dimensional stability, a light weight and excellent total cost of ownership. We also provide thermal-conductive solutions for excellent heat management and design freedom. The Makrolon® RE option is available to enable low- to zero-carbon footprint as a drop-in solution by incorporating attributed renewable content.

Both Covestro and Velodyne are renowned technology-driven companies with strong legacies of innovation. Both companies are committed to creating trendsetting solutions and driving value creation for value chain partners. As global players, Covestro and Velodyne run strong and comprehensive global networks of production sites and innovation hubs, which allow us to be as close as possible to our customers all around the world.

More importantly, the two companies share a common vision on sustainability. We look forward to collaborating with Velodyne to develop more sustainable solutions for the market to drive the transition towards a circular and climate-neutral future together.

China is a vibrant and important market for Covestro. We have worked in China for a long time providing high-performance materials and innovative solutions to meet customers’ needs. Our business activities in China include R&D, manufacturing and sales. Covestro has seven production sites, one regional innovation hub, seven offices and more than 3,000 employees in Greater China.

Covestro has grown stronger over the years since establishing its regional headquarters in Pudong, Shanghai in 2011. Shanghai is also the location of our global headquarters for the Engineering Plastics business entity. Our strengthening business in China was exemplified in 2020 when Covestro upgraded its Shanghai headquarters to become Covestro (Shanghai) Investment Co., Ltd., which undertakes more functions and business scopes such as management, R&D, operations and investment.

In production, Covestro has invested more than EUR 3.4 billion since 2001 into building the Shanghai integrated site, which is the company’s largest site worldwide. Covestro Integrated Site Shanghai (CISS) is now home to 11 plants with the latest technology, covering all major products that Covestro offers and serving industries including construction, automotive and electronics. CISS was granted the National Green Factory certificate by the Ministry of Industry and Information Technology in 2018 for its continuous efforts in using innovative processes that ensure greater sustainability in manufacturing.

Covestro embraces a holistic approach towards innovation. Established in 2001, Covestro’s Polymer Research and Development Center (PRDC) in Shanghai has become the regional innovation hub and provides unparalleled support to customers in the APAC region and to the world.

Velodyne Lidar (Nasdaq: VLDR, VLDRW) ushered in a new era of autonomous technology with the invention of real-time surround view lidar sensors. Velodyne, a global leader in lidar, is known for its broad portfolio of breakthrough lidar technologies. Velodyne’s revolutionary sensor and software solutions provide flexibility, quality and performance to meet the needs of a wide range of industries, including robotics, industrial, intelligent infrastructure, autonomous vehicles and advanced driver assistance systems (ADAS). Through continuous innovation, Velodyne strives to transform lives and communities by advancing safer mobility for all.